The application of airsickness

Corona discharge equipment is suitable for the surface pretreatment of silicone rubber, plastic and other materials, and is used in vacuum electroplating, vacuum coating, splashing, PVD, physical vapor precipitation, printing, pad printing and screen printing

Before printing, adhesive and coating processing, products such as: mobile phone shell, mobile phone keys, P + R buttons, laptops, car lights, car inner decoration, glass lens, household appliances, cosmetics packaging container, washing supplies packaging container, all kinds of sheet material and thin film, paper, fabric, leather, metal, used in paint spraying printing before processing.

Corona processing machine in the packaging industry commonly known as airsickness, electronic impact machine, EDM machine. This is technically known as dielectric barrier discharge. Mainly used for the surface treatment of plastic film or plastic sheet products, when the above materials for ink printing, composite, blowing film, coating, bonding, material modification, grafting, polymerization, coating, flow extension, paste processing, in order to make the surface of the product has a stronger adhesion (that is, with a higher coefficient of Dane), To prevent raw materials in the production process of printing color, composite paste is not firm, coating glue leakage is not uniform and other phenomena, affecting the quality of products, must be first corona impact treatment.

function

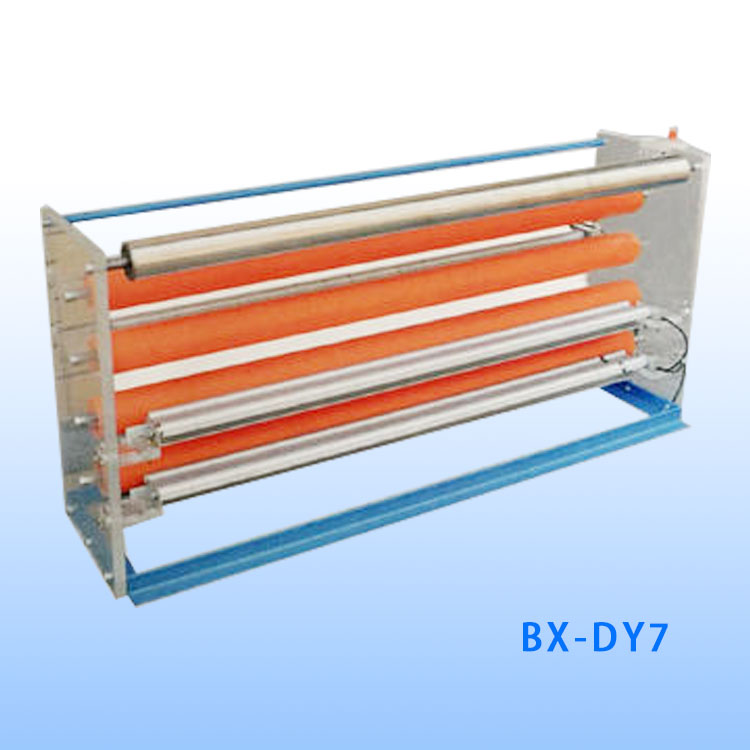

There are different structures depending on the shape of the object to be dealt with, but the electrically controlled part is roughly the same. Thin film corona processing machine is suitable for the treatment of PP, PE, PS, PET, PA, PVC, BOPP, OPP, PT and other material film, sheet surface wetting tension treatment; Metal film corona processing machine is suitable for processing aluminum foil, aluminum plating film and other material film, plate, sheet surface wetting tension treatment; Plate corona processing machine is suitable for PS, ABS, PP, PE and other plastic sheet surface wetting tension treatment; 3D curved surface corona processing machine is suitable for all kinds of plastic parts wet surface tension processing; The cup corona processing machine is suitable for all kinds of plastic, paper and other materials of the cup, hose, sheet surface wetting tension treatment.

Manufacturing electric airsick host adopt stable, advanced, reliable, imported high power IGBT module, the main circuit components, device control, trigger, and shows the main components of the circuit is composed of integrated block circuit, digital display, make the equipment operation is very safe and reliable, durable, low failure rate, and with overpressure overload, over current, short circuit and stalling the advantage such as automatic protection, It is a popular trend in corona field at home and abroad. Due to the use of power device IGBT, the product structure is simple, simple circuit connection, reliable, high efficiency, small volume, simple use, one-key operation, modular structure, easy maintenance, low price.

High voltage transformer is made of oil-immersed high voltage transformer with aluminum alloy shell, which is made of casting and pressing. It has the advantages of beautiful appearance, good internal heat dissipation, durability, no rust, no oil leakage and so on.

To effectively prevent the corona roll stalling, corona spark hit film for a long time and silica gel layer and accidents such as fire, products shall be stalling protection function, make it not only effectively prevent the accident, at the same time greatly extended the corona roll (tube) the life of the silica gel layer, thus effectively reducing the expenses of daily maintenance and wearing parts.

The characteristics of

The high power IGBT power module and drive circuit of the main circuit inverter and the important parts of the high frequency switching transformer, all the integrated circuits of the control part are imported to ensure the reliability of the whole machine.

2 The working frequency of the circuit changes with the change of the load. Through the phase-locked circuit, stable automatic frequency tracking and locking can be realized, which reduces the current and voltage stress of the main circuit power device and makes it in the best working state.

It has soft start function to prevent the pollution of the power grid and the possible damage to the host caused by the impact of the current caused by the high power startup.

4 with three-phase phase-missing, phase-wrong protection, bridge arm through short circuit protection, over current protection, over temperature protection, inverter lock protection, load corona shaft stop protection, electrode holder open protection, load breakdown fire protection.

5 load corona shaft stop protection, electrode holder open protection function can be used, this function is to prevent the rubber shaft because of broken film or other reasons to stop the rubber shaft caused by long-term discharge in the same position of the rubber shaft and breakdown of the rubber shaft.

Technical parameters:

1. Input voltage: 380V±10% 50Hz

2 Maximum output voltage: 15KV

3 Maximum output power: 10KW

4 Working frequency: 20KHz

5. External dimension: control cabinet 600X6001500

Transformer cabinet 410X320X360

6 Weight: 135Kg(control cabinet + transformer cabinet)