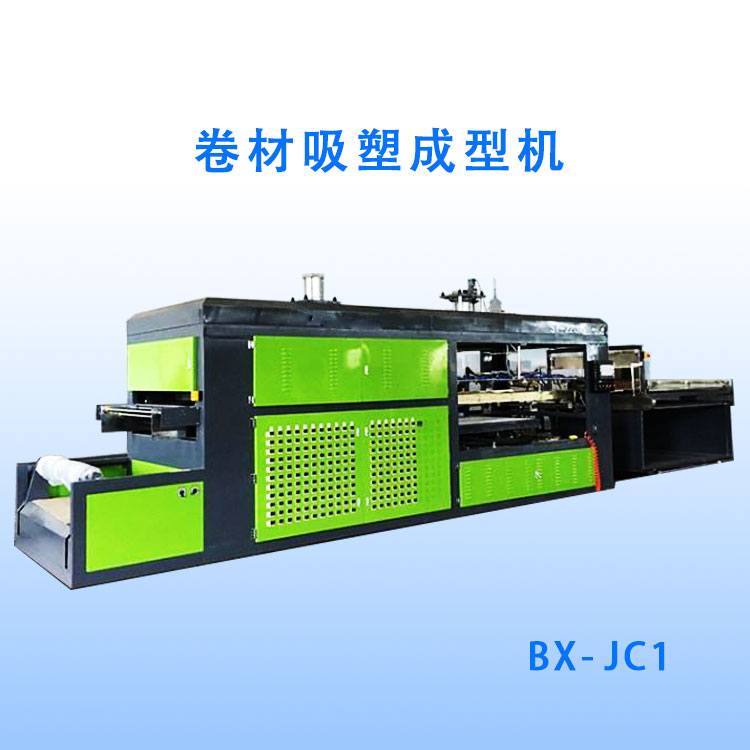

The main structure of the machine is composed of feeding, pulling, upper and lower electric heating furnace, lower gate, multi-function adjustable size, lower die plate, upper die, upper gate, knife gate, slicing, placing and with vacuum device, etc.

And thick piece plastic common products are: household appliances shell, luggage, exhibition rack accessories, decoration, car interior, bumper, fender, beauty equipment, light box shell, toy car shell, industrial panel, advertising light box, plastic LOGO, bathroom products, refrigerator liner and so on

The main use of

1. Plastic packaging industry (Blister packaging, plastic, batteries, toys, gifts, hardware, home appliances, electronics, stationery, decoration)

2. Food packaging industry (fast food boxes, fruit trays, biscuit boxes)

3. Pharmaceutical industry (pill packaging, pill packaging)

4. Industrial cooling tower cooling water guide plate, etc

5. Decorative three-dimensional relief patterns, plastic ceiling, wall panels, automotive materials, sanitary equipment and other manufacturing industries.

6. Suitable for the production of a variety of color sheet: polyethylene PS, PVC, plexiglass, ABS, polymethyl methacrylate; Flocking sheet material; Environmental protection sheet APET, PET, PP, etc. Photodegradable materials; Biodegradable materials and other plastic products

Pay attention to use

1. The power supply must be cut off when the hand reaches under the guide rail to operate, and no accidental power connection can occur

2. When the machine is using the function of secondary mold loading, please do not put your hand into the molding area to touch the cooling products, so as to prevent hand injury when the second mold loading is down

3. In the heating area, do not touch the heating device and baking items with your hands. When the machine is stopped, the heating furnace should be raised

4. When the length of the product is less than 800mm, the action of upper brake and upper die must be synchronized. When the local adjustment machine, should first open the brake, then open the upper die

5. In the local adjustment, such as the use of solenoid valve for debugging, should pay attention to whether the power failure will cause damage

6. When sending the material receiving sheet into the cutter brake and adjusting the position of the slice, the cutter brake should be closed, and the hand shall not be extended into the cutter brake cabinet under automatic state.