The working principle of electrostatic suction ink roller

1. The working characteristics of traditional plate drum and imprint drum

Because in gravure printing, the printing ink is stored within the mesh point of plate, printing machine on the stress transfer ink to substrate, but in this project, because the ink has a viscosity, adhesion and ink on the plate with reason, ink cannot be fully transferred, so will be in white leakage is formed on the substrate, especially in print outlets, Leakage can be very obvious.

Gravure printing machine in the level plate printing machine dot is easy to lose, can not obtain satisfactory results, this is a congenital defect of gravure printing machine, can be controlled from the paper, ink viscosity, printing pressure, tension and other aspects, but it is difficult to fundamentally solve this problem.

2. The working characteristics of electrostatic suction roller

Gravure printing machine installed with electrostatic ink absorption device, you can fully compensate for the loss of dot. Whether paper gravure printing or plastic gravure printing, high security, pulsating voltage more precise, automatic locking, safety protection, the use of integrated circuit is a closed circuit, the machine protection circuit will respond very quickly, cut off the circuit, to ensure the safe and reliable work of the printing press. Through the paper current monitoring system, the ink absorption of the printing press can be monitored and regulated. It has a very wide paper adaptation, its adaptation range is 30~300g of all web paper, it is widely used in stamps, trademarks, coins, cigarette packets, bonds and other high-quality gravure printing with higher color requirements.

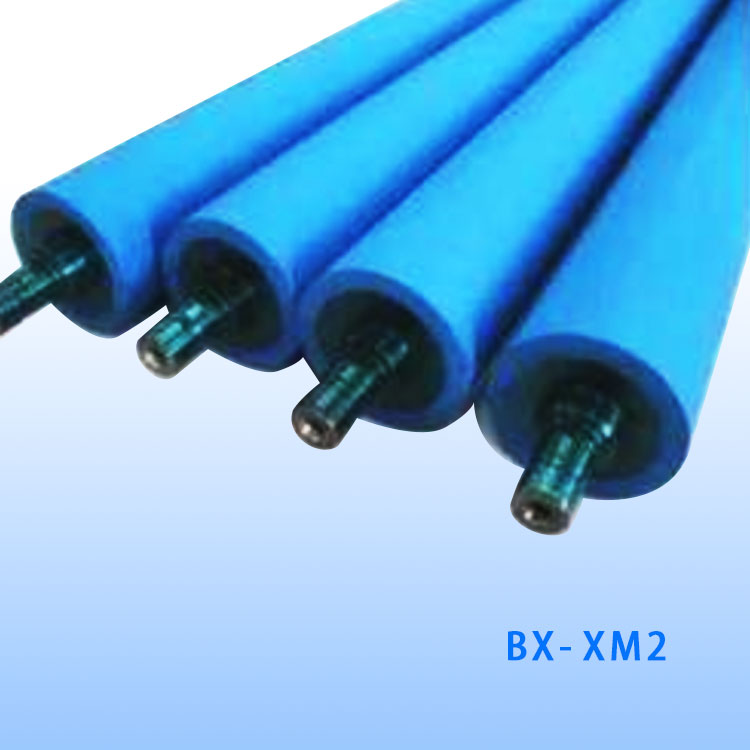

3, electrostatic suction roller working parameters

Hardness 85 ~ 95; Cots hardness tolerance +3, the same root hardness difference +1; Circular runout tolerance ≤0.03m/m; Roller surface without impurities, bubbles, sand holes, mechanical damage, finish Ra0.8; Insulation conducts and resists voltage. In any case, the appearance of the cots is not allowed to be affected by external force and sharp impact, and should be handled gently. The use of dilute cleaning cots, should be wiped with towels, cotton yarn after wring dry, to be completely dry appearance can be used. Cots should be placed or support journal storage, do not squeeze each other together. Commonly used specifications with shaft roller can be hollow roller two categories.